Life extension – wear parts for coal pulverising mills etc.

AGJ A/S has substantial experience in welding, hard surfacing and service life extension of wear parts for coal pulverising mills, crushers, environmental plants, etc.

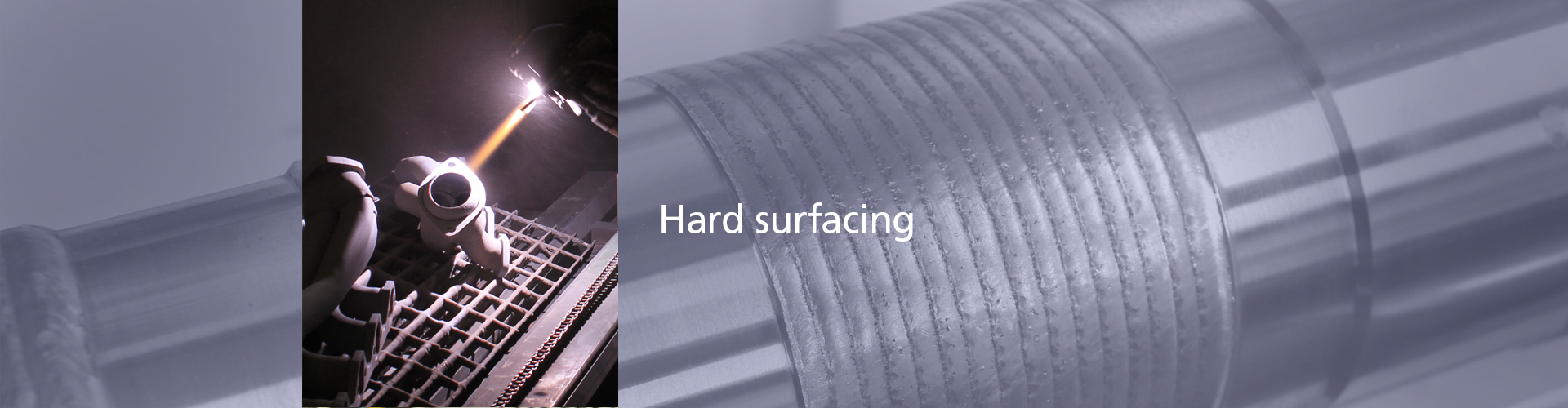

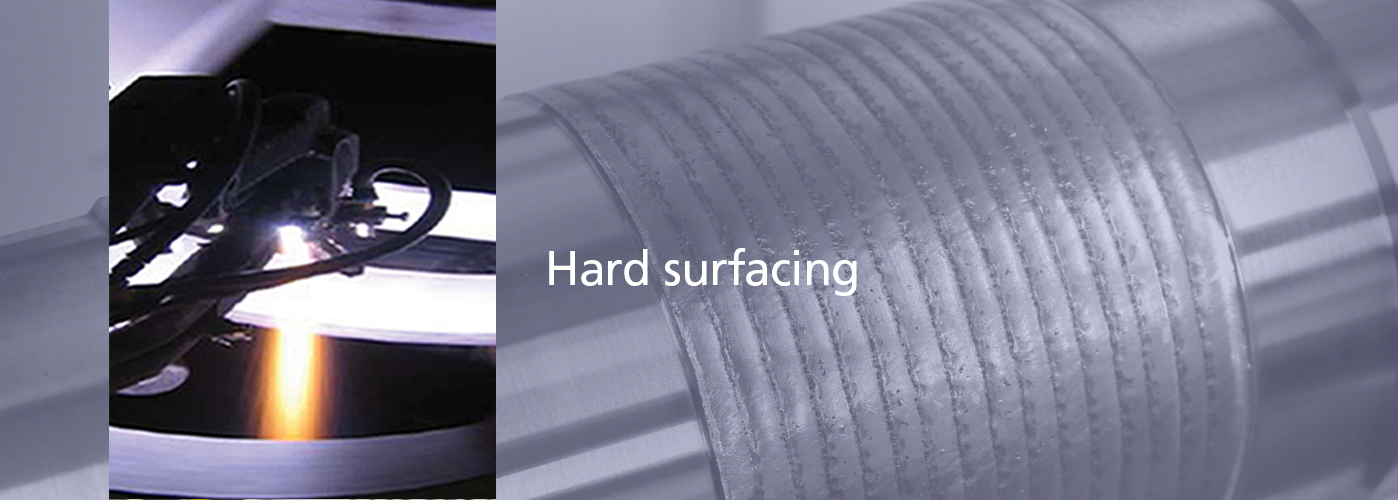

Service life extension is usually done by welding specific wear parts, using MAG welding and open arc with carbide-filled flux-cored wire, or PTA welding using wolfram carbides. AGJ A/S has equipment to undertake efficient welding of components on-site in our clients coal pulverising mills or processing plants, or we can complete repair jobs using welding and hard surfacing of e.g. rolls of up to 5,000 kgs. in AGJ A/S Production facility Stenlille.

For our clients, welding with e.g. AGJ Corthal 55Mo on table or rolls suitable for Loesche coal pulverising mills generally means a life extension from ca. 4,000 operating hours to more than 9,000 operating hours. Besides this evident economic advantage our clients obviously obtain fewer breakdowns per year, longer intervals between repair and maintenance, together with reduced costs for maintaining wear parts in spare parts store.

AGJ A/S is experienced in repair, maintenance and service life extension of wear parts for coal pulverising mills of the types Loesche, Berz, Pfeiffer and Raymond.

AGJ A/S offers to perform service life extension on many other applications for the cement industry, environmental engineering, incineration plants, etc.

We collaborate with some of the leading manufacturers of filler materials and carbide-filled flux-cored wire in Europe. Usually, carbide-filled flux-cored wire of up to dia.3.2 mm, of the types AGJ Corthal 55Mo, 337, or 740F is used. Depending on our clients’ challenges when it comes to wear, we offer applications with more than 150 different types of filler materials and qualities.

Welding equipment for automatic open arc hard surfacing is supplied by ESAB and operates efficiently at 600A maximum permissible continuous current, ensuring a regular and stable heat-input via the design of the machine torch and automatic stick-out regulation. All welding parameters are of course defined according to prescribed WPS and welding procedures. All executed work is handed over with full documentation according to En 15614 and certificate for filler materials according to En 10204 3.1. For our clients, this provides significant advantages quality-wise as compared to welding performed with manual equipment.

Some of the most significant economic advantages of welding/hard surfacing of wear parts for e.g. coal pulverising mills are:

•Regulated heat input resulting in minimal “incineration” of wolfram carbides and minimal dilution with the base material. These are significant parameters for increased wear resistance.

•Regulated melting of flux-core wire and controlled molten pool by automatic stick-out regulation is of great significance to nice wear surfaces and increased wear resistance.

•Automatic welding and full control of the process parameters at the welding equipment’s level of automation results in optimum and consistent quality of the surfacing.

•Efficient welding resulting from the welding machine’s ability to operate at the maximum permissible continuous current of up to 600 A is, of course, the key to efficient production and a competitive manufacturing price.

•Trained staff with the right expertise within welding wear parts for e.g. coal pulverising mills. Our welding operators know their material.

•Technical support is provided by AGJ A/S’ welding operators, our engineer or our welding technician (IWT), which enables us, in collaboration with you, to find the optimum wear-resistant solution for your processing plant. If necessary, technical support may be provided by one of the leading manufacturers of flux-cored wire and carbides in the world.

If you are interested in discussing our options to offer service life extension on your wear parts or machine application, please contact AGJ A/S.

.

.