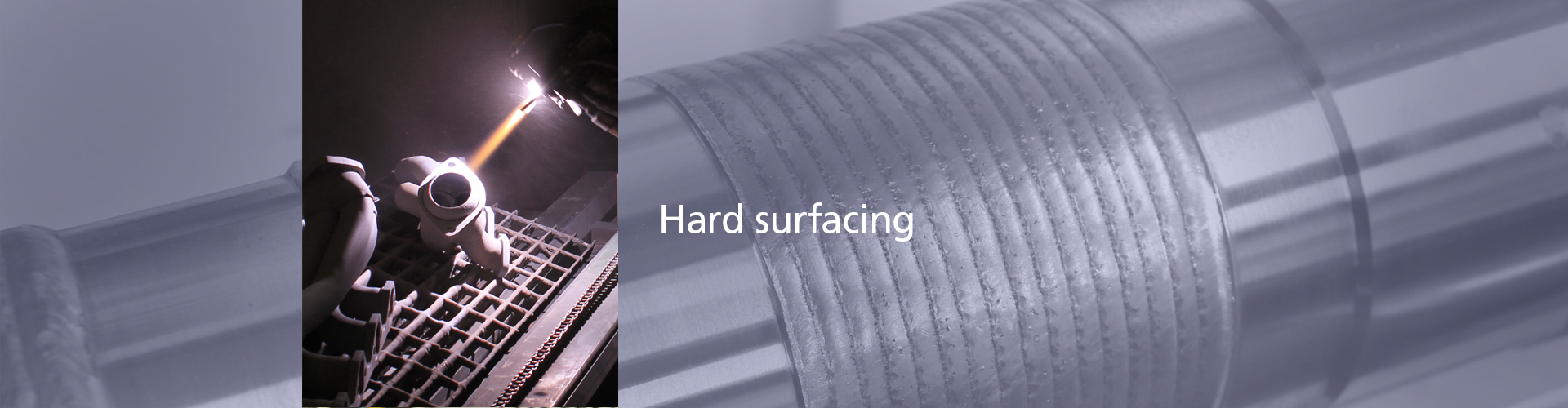

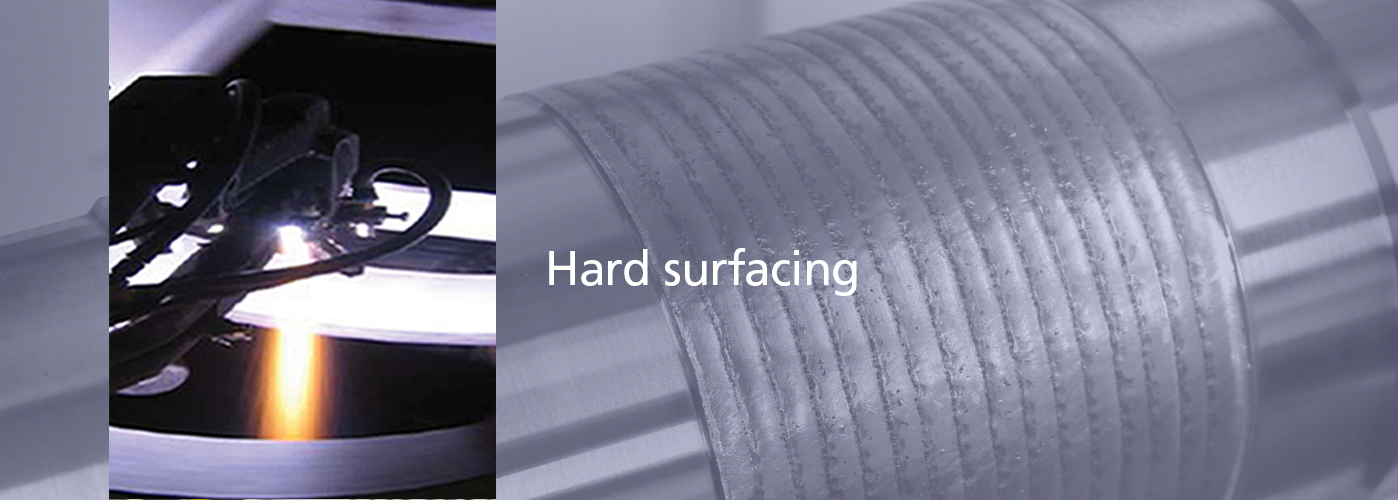

Thermal Spraying

AGJ A/S offers hard surfacing performed with a variety of different methods within thermal spraying, which may be divided into cold and hot spraying processes.

Cold spraying processes are: arc spraying, flame spraying, plasma spraying or thermal spraying with HVOF equipment and these methods may be executed where the filler materials are powder or thread.

Hot spraying processes are likely to be flame spraying using filler materials in powder form, where the material sprayed on is finally brought up to fusing temperature and a completely homogeneous surfacing with impact-resistant eutectic bonding to the starting material is obtained.

AGJ A/S often uses plasma spraying, as we have experienced good results with consequently high adhesion and very dense surfaces up to 92-98 %. The particle velocity of plasma spraying is 200-500 m/s. and the plasma jet’s operating temperature is up to 20,000C.

Plasma spraying is used on shafts, bushings, crushers, propellers, spiral screws, worms, rolls, blades, etc. in a variety of industries. Often, plasma spraying can be used with the advantage that this technique is more inexpensive than flame spraying with HVOF equipment.

Videos

.

.