AGJ Piping – piping in the pharmaceutical industry and in power plants

Since 1963 AGJ A/S has performed an ever increasing amount of pipe jobs for our industrial clients in the pharmaceutical industry and on power plants in Scandinavia. Our teams work according to the strict quality standards required by our clients in the pharmaceutical industry, amongst others, and those which are required by the Danish power plants. We work according to welding standards under DS/EN ISO 3834 and the PED 2014/68/EU. Our blacksmiths can perform certified pipe jobs in thin-walled dairy pipes, plastic pipes and heavy-walled black pipes and pressurised plants.

The core of our staff includes well-educated blacksmiths, pipe layers and certified welding operators, who are supported by our welding specialists (IWS), our welding technician (IWT) or our technicians in AGJ Engineering. Consequently, we offer our clients substantial experience when it comes to industrial piping jobs. The team has at their disposal the latest orbital welding equipment and TIG welding equipment, and also endoscopy and pressure test equipment for carrying out our own inspections.

Orbital welding PED

In AGJ Piping our certified welders perform orbital welding in piping systems build in thin-walled pipes. When our customers have specific demands for a consistent, homogenous and smooth surface, we use orbital welding. Orbital welding is a perfect solution for the food- and pharmaceutical industry, where we guarantee an even and hygienic weld – every single time. We orbital weld, test, document and deliver a project in top quality – every time.

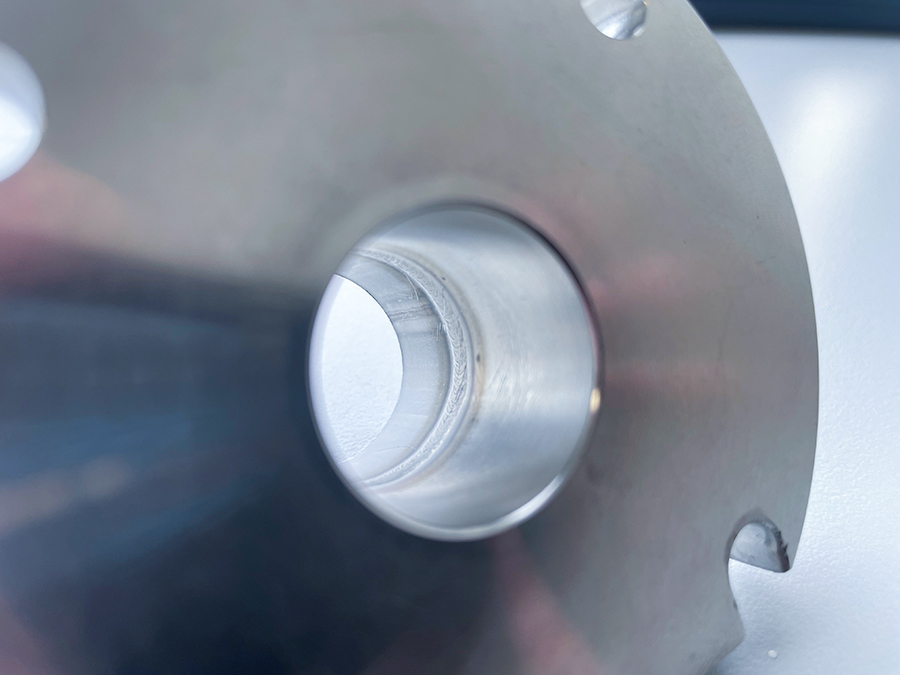

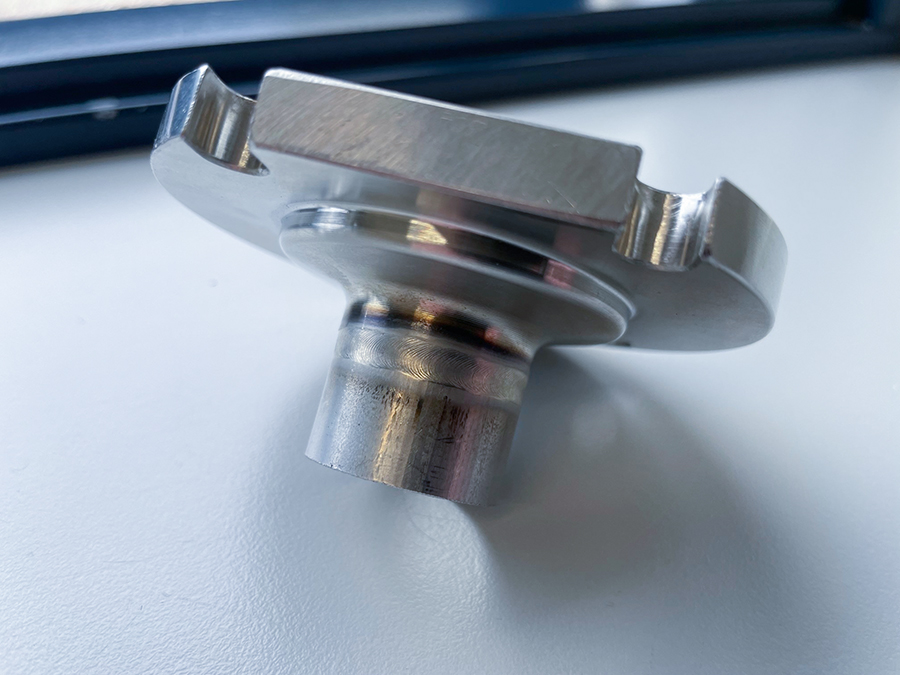

February 2022: Orbital welding close to edges and endnings close to flanges and valve houses

AGJ A/S has invested in yet a new orbital welding machine from german Orbitalum. The equipment is a Orbimat 180 SW, and it strengthens the teams compiled welding capacity significantly in relation to delivering welding projects at the highest level to the food- and pharmaceutical industry. With the new Orbimat, we weld thin-walled pipes in dimension from ø25mm to ø76,1mm.

The new, special designed welding head entails an optimized welding quality, as we are now capable of welding very close to edges and endings meeting flanges and valve houses. Our new Orbimat is special designed in an extra compact edition enabling the equipment to work in our customers galleries and pipe avenues.

Do you need orbital welding in your plant – call Peter Jørgensen and have a talk about the project. Go to contact page.

Pictures of traditional orbital welding

Pictures of orbital welding with the Orbimat 180 SW

.

.