News from the team in AGJ

AGJ delivers container solutions to entrepreneur

AGJ Container Trading has completed an order of specially designed exhibition containers for one of the biggest entrepreneurs in Denmark View all your possibillities on the new, specially developed website for AGJ Container Trading. (Website in danish).

AGJ sponsoring Ronnie Bremer in DTC racing

AGJ A/S is sponsoring the danish racing specialist Ronnie Bremer. AGJ A/S supports in the last three races of 2016 i the DTC class. We wish Ronnie all the the best in the closing races of the DTC class.

New large investments in stainless shop

AGJ invest in a new big workshop for stainless production. The workshop is build separately from the rest of our production facilities to eliminate the risk of contamination of our stainless constructions with non stainless particles. To accomplish this 100% trustworthy, AGJ has invested in two brand new processing machines.

AGJ A/S installs radar foundation on the Navy’s frigates

Teams from AGJ A/S do installations of radar foundations on the Navy’s frigates on the Naval Station of Korsør, located south-west of Copenhagen. The work is being carried out on the PETER WILLEMOES & NIELS JUEL frigates in close collaboration with naval architects from FMT and staff on the Naval

AGJ A/S ISO Certified in acc. to EN ISO 3834-2 and EN ISO 1090-1

The team of AGJ A/S is now ISO-certified. Form October 2014, the team has achieved official ISO 3834-2 and ISO-1090 certification. We can now offer our customers welding and construction work incl. CE marking in accordance with applicable standards, in all steel and aluminum structures. The statutory CE Marking ensure full documentation and

Green Smiley to AGJ for AMO’s Work with Health and Safety

AGJ A/S has assigned a so called “Green Smiley” by the labor inspectorate adapted probation. Management expresses pride the we have managed to achieve this recognition, for the teams work with Health and Safety in the Company!

AGJ A/S exhibits at AJOUR 2014 on November 27 & 28 2014

Once again, AGJ A/S will be exhibiting at the Engineering Association Trade Conference, AJOUR 2014 in Odense Conference Centre. The trade fair will be from Thursday November 27 to Friday November 28 2014. AGJ A/S will once again be exhibiting at standplace number 4300. We hope to see many of

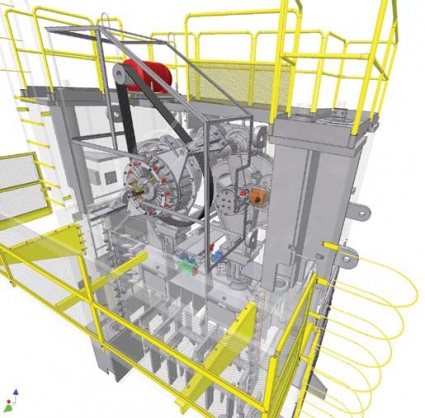

AGJ A/S and Process Engineering manufacture processing plants

Team AGJ A/S manufactures hydrogen processing plants for a Danish industrial client in close collaboration with Process Engineering. The unit is built with a steel construction, where various process components and reactors are installed and connected by more than 600 m Swagelog pipe systems. The final test and pressure testing

AGJ A/S initiates welding with wolfram carbides in coal pulverizing mill

Our hard surfacing specialists perform hard surfacing with completely new optimised welding equipment on coal pulverizing mills for Vattenfall A/S. The work is done as MAG welding and open arc with carbide-filled flux-cored wire. Welding is done with dia.2.8 mm application specific AGJ flux-cored wire and WPS set up by

AGJ A/S offers industrial service of conveyer belts

AGJ A/S offers industrial service performed on conveyer belts, knife scrapers, gear motors, motorised conveyer pulleys, etc. We offer installation of special engines, new knife scrapers, new rubber belt of various quality and standards, and industrial service of transport elements in your industry 24 hours a day. We offer industrial

AGJ A/S assists in the repair and maintenance in Vattenfall A/S

AGJ A/S is assisting Vattenfall A/S in the repair and maintenance of Fynsværket (a large power plant in Funen). A small team has reviewed the bearings at turbine plants in unit VII. In addition to this, Metalock Engineering Sweden AB and AGJ A/S have done turning of flanges with portable

AGJ A/S performs service life extension of wear parts for coal pulverizing mills

AGJ A/S performs hard surfacing with open arc and carbide-filled flux-cored wire on rolls and table for coal pulverizing mills on one of the largest power plants in Denmark. Welding is done with dia.2.8mm flux-cored wire from the German Corodur, and WPS is set up by a welding engineer from

AGJ A/S performs certified welding on pollution-combating vessel

Certified welding operators from AGJ A/S perform welding on the pollution-combating vessel Gunnar Seidenfaden. The task is performed by employees who have obtained the necessary experience in solving welding repair assignments in the naval industry.

NORSOK and Achilles audit AGJ A/S

AGJ A/S has just been audited by NORSOK & Achilles Joint Qualification system (JQS) ID no. 27822. The team has obtained fine results with the review of our management systems and auditing, which stresses that AGJ A/S is qualified as a competent sub-supplier to clients in the Scandinavian energy sector,

AGJ A/S obtains pre-qualification with Sellihca

Based on increasing demands on quality from our clients, AGJ A/S has obtained certification and pre-qualification with Sellihca ID no. 110703 from 1 January 2012. Sellihca has approved our quality control system and the general qualification level of our team. The pre-qualification from Sellihca stresses the fact that AGJ A/S

Team AGJ A/S manufactures corrosion-resistant radar foundations for the Defence

AGJ A/S has just supplied three new radar foundations for the Defence’s new frigates. The foundations are manufactured according to special WPQR and WPSs and meet the new welding standards according to DS/EN 1090, which took final effect in the summer of this year. AGJ A/S have manufactured, supplied and

Team AGJ A/S works on pipe project for district heating

A key team from AGJ A/S is in the process of reconstructing and renovating booster stations in the district heating system in West Zealand. In our workshop in Stenlille our certified welding operators are in the process of prefabricating pipe systems according to the P&I diagrams and ISO standards for

AGJ A/S executes new pipe system in the pharmaceutical industry

Our team in Kalundborg has just completed a major project with our client in the pharmaceutical industry. The assignment consisted of establishing pipe systems and assembly of various components around a spray drier system used in the manufacturing process. The project is completed and handed over, including documentation, according to

AGJ A/S executes hot-tapping on methane-filled pipes

AGJ A/S executes hot-tapping of pipe systems filled with methane gas via close collaboration with our supervisor and our client in the power plant industry. Working with blow-down of methane-filled pipe systems is done using special tools under strict safety measures. Read about the process of hot-tapping on www.hot-tap.dk, or

AGJ A/S manufactures and balances impellers

AGJ A/S has the equipment, expertise and competence at our disposal to be able to offer manufacturing impellers for industrial fans in the power plant industry and in chemical processing plants. We offer manufacturing from measurement, construction and welding, to coating with wear resistant surfaces and final balancing. We offer

Plastic pipe systems in PP, PE, PVC or PVDF from AGJ A/S

AGJ A/S offers our clients pipe systems created in PP, PE, PVC-U or PVDF pipes for process water or oil and chemical products. We make client-specific pipe systems in plastic and supply a turnkey solution created with the necessary certification and documentation. We collaborate with some of Europe’s leading manufacturers

AGJ A/S expands the portfolio with hard surfacing

AGJ A/S is offering the use of hard surfacing of various spare parts and machine component for our clients with wear problems. In this context we collaborate closely with several Scandinavian experts who have modern equipment for hard surfacing at their disposal. Moreover, we are in close collaboration with the

AGJ A/S establishes corrosion-resistant production facility in Stenlille

AGJ A/S expands our portfolio with corrosion-resistant operations in Stenlille. The team now has workshop facilities available in Stenlille, where prefabrication of various pipe systems and manufacturing of various products in corrosion-resistant and acid-resistant materials is completed. The teams’ goal is to have the workshop in Stenlille act as a

AGJ A/S offers industrial service with specialised tools

AGJ A/S now offers machining with specialised tools when providing service and maintenance in the energy and processing industries. We have developed an expertise in pipe processing in connection with welding, flange and valve processing, electrical, hydraulic and pneumatic fastening of bolts with torque tools and NDT with pressure testing

AGJ A/S supplies wolfram-surfaced friction plates and shims

AGJ A/S now manufactures a large quantity of friction plates and shims surfaced with wolfram carbides. In the past months alone we have supplied more than 6,000 laser cut plates, surfaced with wolfram carbides. We use PTA spraying equipment and robot engineering for manufacturing current wear plates. Management considers the

AGJ A/S offers portable processing of machine components

AGJ A/S now offers portable processing of flanges, sealing covers, turbine and generator casings, etc, for those of our industrial clients who may need it. We are capable of processing pipe flanges and packing faces on turbine casings or bearing seals all the way up to dia. 3,000 mm. in

AGJ A/S focuses on complex steel constructions

At AGJ A/Ss production facility in Stenlille our team is now focussed on producing complex steel constructions for industries that make increasing demands on quality. We work according to DS/EN 1090-2 and existing EUROCODE 1 – 3. Our teams in AGJ-Production and AGJ-Engineering collaborate on setting up particular welding procedures

AGJ A/S trains apprentices and re-certifies welding operators

To strengthen our teams for future competition, our staff has just been increased so that we now train and employ as many as six apprentices. We concentrate specifically on training young people to ensure the development of the best possible future for AGJ A/S. At the same time, the team’s

AGJ A/S welds pipe installations by means of orbital welding

AGJ A/S performs orbital welding with modern automatic welding systems. AGJ A/S provides maximum welding quality on pipe work for assignments where increasing demands on quality are made, such as in the pharmaceutical industry. Currently, the team includes as many as three employees who can perform certified welding with orbital

AGJ A/S offers 3D CAD construction

As part of the strategy to continuously supply ‘a complete package’ to our industrial clients, the AGJ A/S team’s Inventor version is upgrading to the latest 2011 3D CAD system. Thus, our technicians in AGJ Engineering are capable of offering our clients overall solutions from idea and engineering, to drawing,

.

.