Vapor Honing

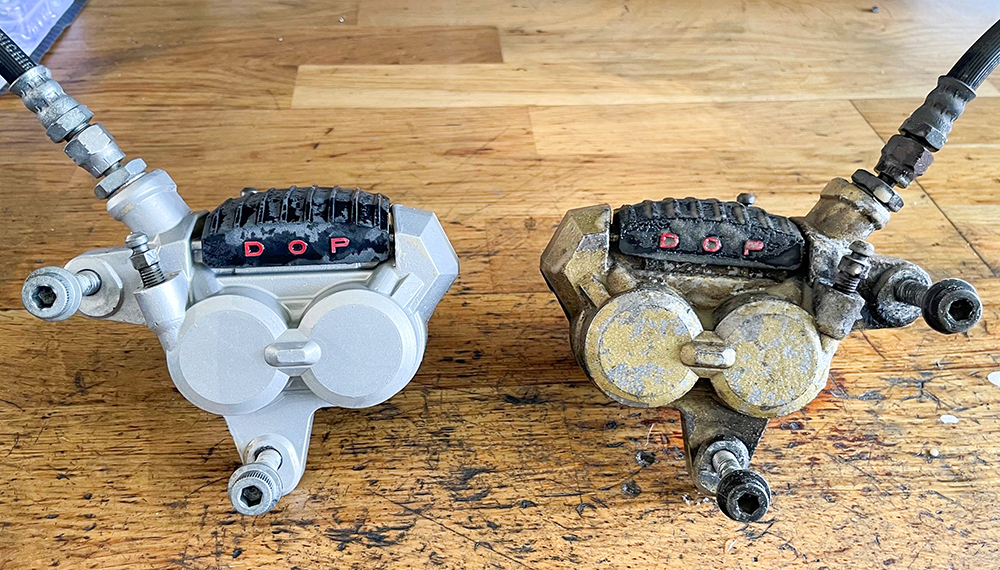

As something new in AGJ Hard Surfacing, we offer VAPOR HONING on all workpieces, where the outcome is expected to be silky smooth, and where the surface treatment is gentle and doesn’t remove material.

Vapor Honing is performed in a specially designed cabinet, where specially hardened glas pellets and water under pressure remove impurities from your motor components, transmission parts or industrial machine components. Cleaning with vapor honing is performed in a closed water circuit, and as a result of this, it’s a completely green technology to achieve a super finish on your workpieces.

In AGJ VAPOR HONING we hone all pieces produced in aluminium, magnesium, stainless steel, titanium, brass, bronze, plastic and rubber. We execute the jobs on modern vapor honing equipment from the american company VAPOR HONING TECHNOLOGIES.

Vapor Honing is especially suitable for renovating motor components as e.g. pistons, crankshafts, conrods, cylinder heads, caps and covers in aluminium or magnesium, crankcases, transmissions etc.

Vapor honing is especially suitable for industrial workpieces, that has to be delivered with a silky smooth and matte surface after processing. Watch the photos on this page.

Call Tim Christoffersen with requests on renovating motor parts or machine components on +45 51 16 85 95.

AGJ HARD SURFACING – Quick and effective vapor honing of your spare parts!

.

.