HVOF Technique

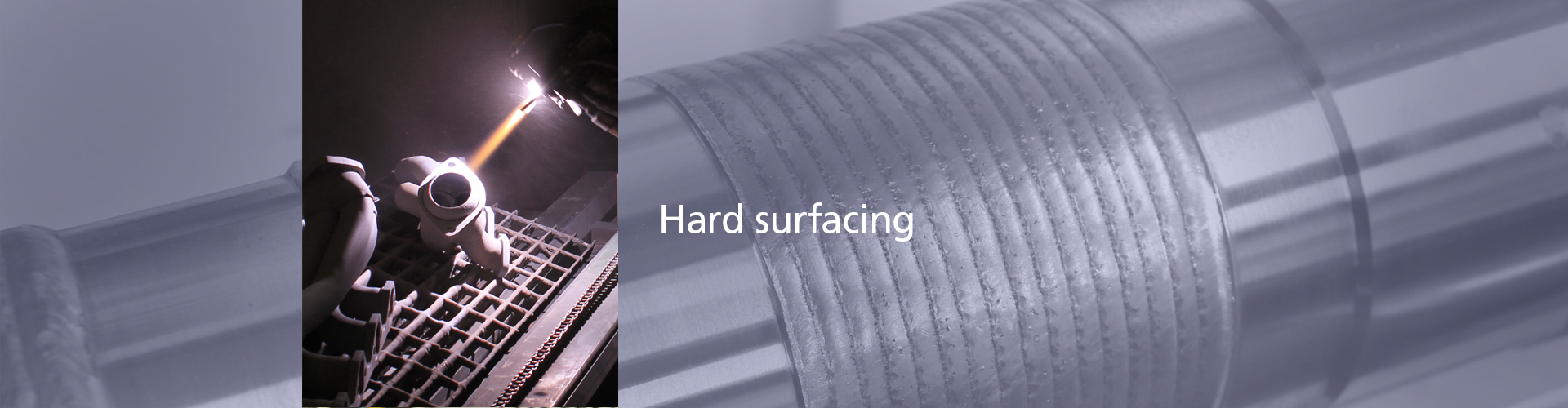

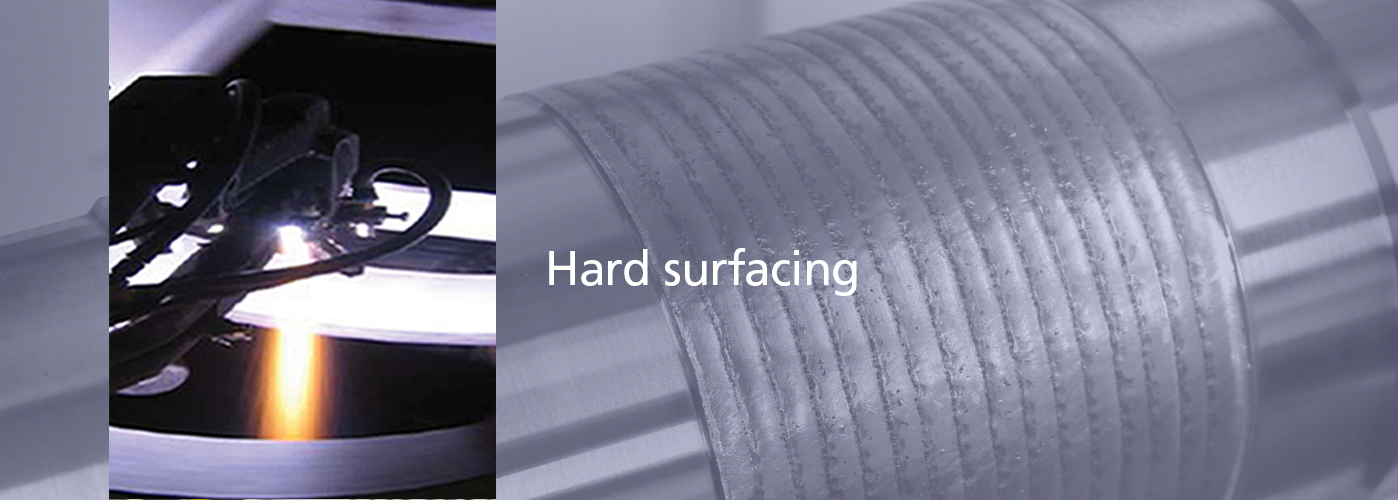

AGJ A/S offers hard surfacing with e.g. wolfram carbides and thermal spraying with HVOF equipment (High Velocity Oxygen Fuel).

The HVOF technique is a relatively recent method developed within thermal spraying. This method generates extremely high excitation energy in the heated particles, which are typically wolfram carbides, when they hit the surface to be surfaced. During the working process, the particle velocity is 900 – 1,200 m/s and flame temperatures typically reach ca. 2,600C.

This high excitation energy causes the surfacing to become highly adhesive when sprayed on the part; simultaneously, the microstructure on the surfacing becomes very dense and homogeneous, up to as much as 99-99.5 %.

The HVOF method is used for shafts, flywheels, gear wheels, bushings, worms, etc., that are exposed to extreme wear, and where the demand on quality is at its highest level.

Our team is able to execute flame spraying with portable HVOF equipment at repairs on boiler plants in power plants. The pictures on this page annotate our work in repairing packing faces on the turbine casing for the LP turbine for Vattenfall – Amagerværket. The assignment was completed with portable HVOF equipment in connection with the summer’s repair and maintenance on the turbine in question.

Video

.

.