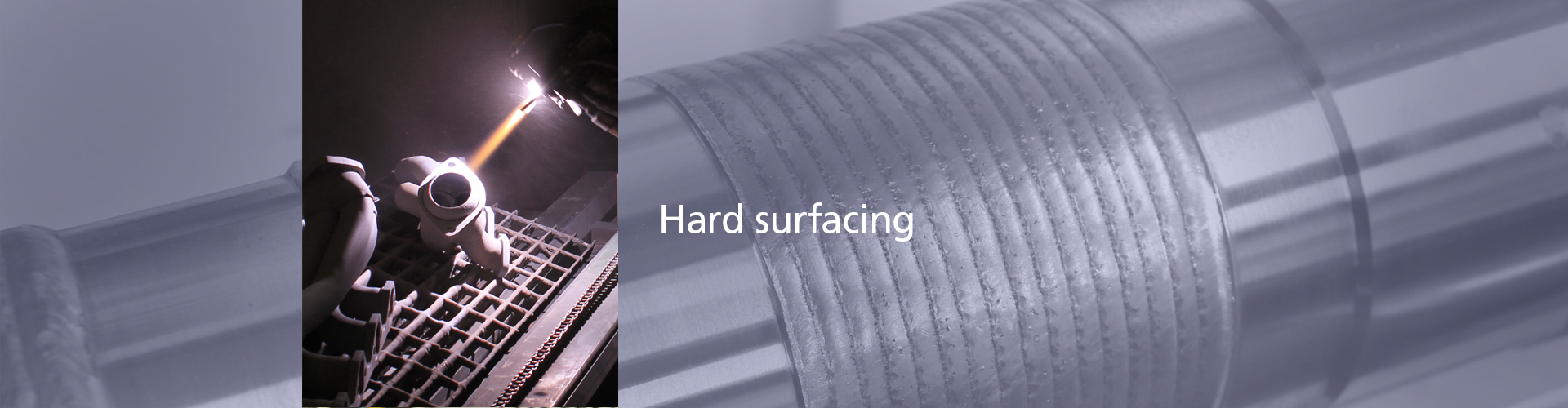

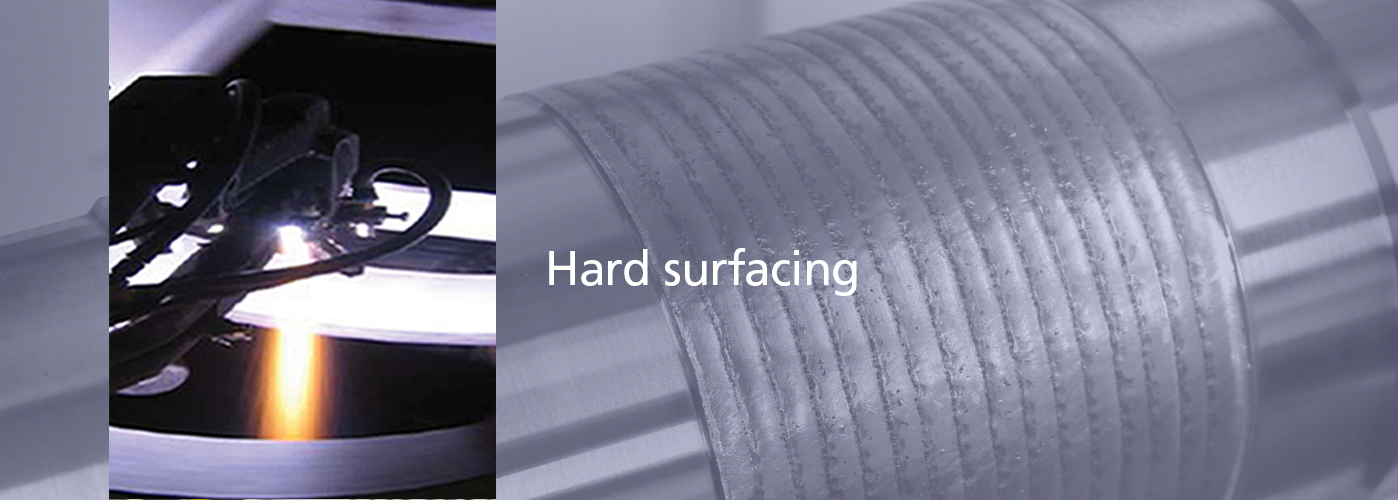

Hard surfacing — PTA Welding

AGJ A/S can offer hard surfacing executed by PTA welding.

PTA welding is not a thermal spraying method but rather a welding method where a definite dilution takes place with the base material. However, the dilution with the base material is limited (1-5 %) compared to other traditional welding methods, this is why PTA welding can be a good alternative to thermal spraying for certain applications where a homogeneous impact or pressure resistant coating is required.

The filler material is often in powder form, but we have performed assignments where this has been in fibre form, together with our Swedish collaborator. A common feature of our methods is that the heat source consists of gas plasma, hence the name PTA (Plasma transferred Arc).

We have completed assignments by using PTA welding and materials such as Stellite on applications for the oil and gas industries, and valves and components that are to be used in the power plant industry.

PTA welding with e.g. wolfram carbides on wear parts for construction machinery or spare parts for agricultural machinery can be used with great advantage because this type of welding often increases wear resistance significantly, resulting in service life extension.

As a welding alternative we offer MAG welding with powder-filled flux-cored wire on machine components exposed to wear, such as rolls and coal pulverising mills. By using the correct flux-cored wire and performed with a relatively low heat input, MAG welding may be used as an inexpensive alternative to e.g. PTA welding. Flux-cored wire is usually supplied directly from the manufacturer in Germany.

Video in danish

.

.